Three-dimensional Self Assembly of Graphene

Three-dimensional (3D) graphene is known to have numerous applications as adsorbent, catalysts, sensors, energy storage such as batteries and super-capacitors. Further, 3D graphene is easy to handle and convenient to load as adsorbent in a packed bed.

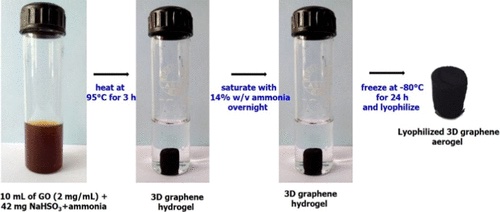

One of the ways of preparing 3D graphene is through reduction of 2D graphene oxide particles which leads to self-assembly of the reduced graphene particles in to a 3D “house of cards” type structure, as seen in the figure below:

(Ganesan and Juvekar, ACS Appl. Nano Mater. 2020, 3, 11, 10823–10834)

However, this resultant structure has to have mechanical strength as well as flexibility and compressibility so that it is amenable to be used as packing in large scale industrial columns. At the same time, the surface area of the original 2D graphene oxide must be preserved, to the extent possible, so that the properties of 2D graphene such as conductivity and surface area are conserved. Previous work done on this topic can be found on this link: https://doi.org/10.1021/acsanm.0c02108.

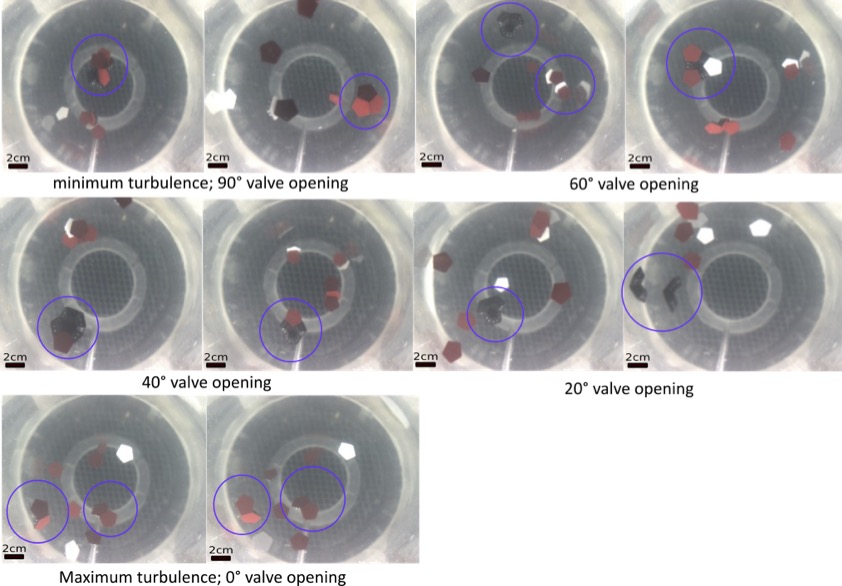

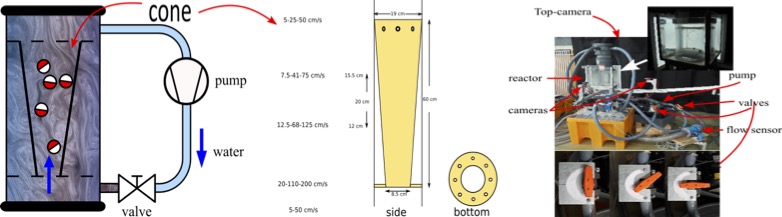

The aim of this PhD topic would be to develop techniques for preparation of 3D graphene in order to achieve desired characteristics as mentioned above. Influence of methods of reduction, types of reducing agents, kinetics of reduction and various other parameters on the number as well as strength of connections between reduced graphene particles will be studied. The dynamics of the self-assembly will also be studied through an analogous experimental system involving 3D printed sheet-like particles representing graphene (see figure 2 below). Embedded magnets in the particles will be used to tune particle-particle attraction.

These studies will be performed using an existing macroscopic self-assembly reactor shown below.

This work is in collaboration with Dr. Per Loethman of Foviatech GmBH (https://www.foviatech.com). The selected student may spend some time at our collaborator's lab in Germany. A collaboration with University of Delft in Netherlands is also foreseen.