Jyoti Seth

Core Faculty

Associate Prof.

241, Chemical Engineering

Core Faculty

Associate Prof.

Eiffel Doctorat Fellowship (2006-2007)

EGIDEGujarat Ambuja Cement Award (2001)

Complex glasses formed from micro-emulsions are a relatively recent discovery and provide an elegant way to arrest the self-assembled microstructure. Mixture of sugars form the polar component for the micro-emulsion that undergoes vitrification a little above room temperature, paving way to prepare stable arrested solid micro-emulsions resistant to phase separation or structural transformations. An experimental procedure has been developed to prepare such “complex glasses” from the one-phase bicontinuous micro-emulsions. We are exploring use of these nanostructured glasses as templates for formation of polymer membranes with nano-pores and other functionalized composites.

Because of their aspherical shape, anisometric particles have a low percolation threshold and form a space-percolating network at low volume fractions. We study how the self-similar structural hierarchy is generated when suspensions of anisotropic particles are prepared through the process of crystallization. Suspensions containing fatty acids and their triglycerides are quintessential examples of crystalline systems where dynamics of crystal growth, aggregation and resulting suspension behavior can be studied. Further, certain additives, even in minute quantities, can influence the choice of polymorph and/or face dependent growth kinetics of crystals. This proves critical for industries where rheology of the suspension is critical for performance, stability and perceived quality.

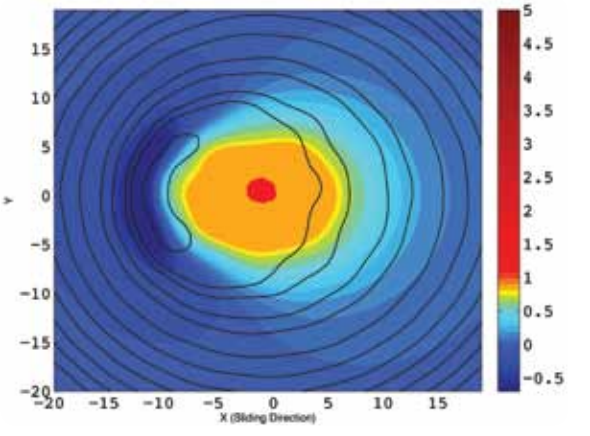

We are studying lubrication flow dynamics around naturally occurring rough topographies. We solve for deformation of elastic surfaces of different roughness along with the Reynold’s equation for lubrication flow in between and around asperities. Surface and pressure profiles, and the effective drag and lift forces experienced by the soft body compare against experimental measurements made with rough elastic substrates. The model is being used to extend our understanding of lubrication flow of non-Newtonian fluids between soft confinements.