Akkihebbal K Suresh

Emeritus Fellow

Professor

224, Chemical Engineering

Emeritus Fellow

Professor

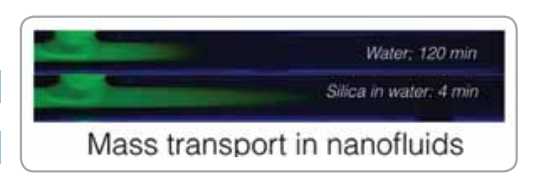

Nanofluids are suspensions of particles in the nanometer size range in conventional fluids. We have demonstrated that the mass transfer rates in such fluids is much higher (often by a factor or 2 or more) than in the base fluid alone. In ongoing work, we are attempting to (a) understand the physical basis of this effect both experimentally (through measurements of diffusivities in quiescent nanofluids) and theoretically (through multi-scale simulations), and (b) map the regions in the parametric space where substantial enhancements may be expected in industrial-type contacting equipment.

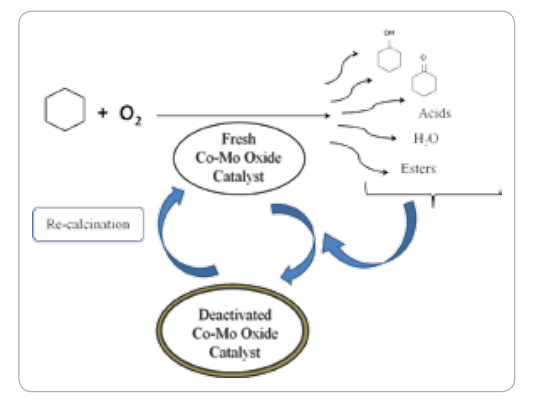

LPOs are an industrially important way to functionalize a variety of hydrocarbons and oxygen-containing compounds, but their complex chemistry and involvement of transport resistances make them difficult to study and optimize. The recent trend in this area is towards heterogenizing these reactions. A mechanistic study of various uncatalyzed and catalyzed oxidations (cyclohexane, glycerol are two examples) are being undertaken to understand the catalyst-support interaction with various catalysts, and also the reaction-engineering aspects in industrial type reactors.

Conventionally, solid-solid reactions have been treated using models similar to solid-fluid reactions. However, in general, we need to explicitly account for the discrete nature of contact between reactants in such cases (and hence the complicated geometries that arise when reactions proceed from such contact points), since the conventional treatment often leads to inconsistent values for the rate parameter estimated (Diffusivity in most cases). We have derived approximate models to treat such situations and also derived some conditions under which the conventional treatment may suffice. In ongoing work, we are trying to rigorously solve the problem using a finite-element technique, and hence establish the regions in the parameter space where different approximations are tenable. The models are also being tested via experiments on calcia-alumina and other systems.

Several gas-separation membranes and RO membranes are made by polymerization techniques in which the conditions of synthesis have a significant influence on the structure, and hence function, of the membrane. Interfacial polycondensation is a reaction that is actively being investigated in our group. Novel methods have been developed to follow the kinetics of these fast reactions and relate them to the structural features of the films that form. Other themes such as performance enhancement through particle incorporation are additional areas of interest.