Yogendra Shastri

Core Faculty

Professor

311, Chemical Engineering

Core Faculty

Professor

Certificate in Foundations of Teaching Center for Teaching Excellence University of Illinois at Urbana-Champaign: 2011

Prairie Project Sustainability Curriculum Development Program University of Illinois at Urbana-Champaign: 2011

AIChE Environmental Division graduate student paper competition winner: 2007

DAAD (German Academic Exchange Service) scholarship to University of Stuttgart: 2002-2003

AIChE CAST (Computers and Systems Technology) Division travel award: 2007

Development of an integrated biorefinery that produces biofuels as well as low volume, high value co-products could make microalgal biofuels techno-economically feasible. The synthesis of such an integrated biorefinery is challenging due to multiple pathways, products, and design specifications. Our work addresses this challenge by performing model-based superstructure optimization. Important stages in biodiesel production, namely, growth, harvesting and dewatering, lipid extraction, and transesterification are modelled. For each stage, several potential options are considered. The objective function is minimization of the net annualised life cycle cost of biodiesel production for a fixed annual demand. It is a mixed integer linear programming (MILP) problem, which is modelled in GAMS and solved using the CPLEX solver. The model will be extended further to consider the production of value added co-products.

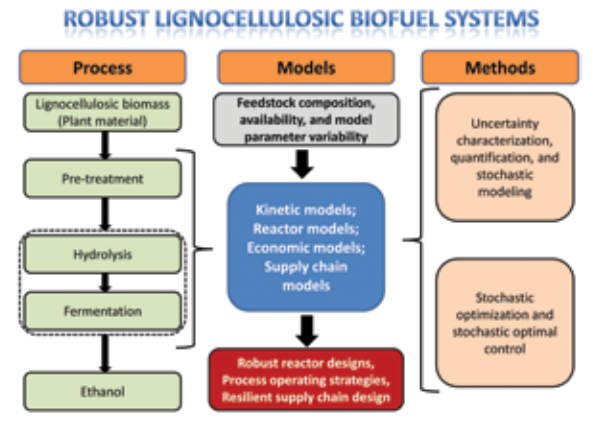

Biochemical processing of lignocellulosic feedstock into fuel and value added products is impacted by various static and dynamic uncertainties such as feedstock quality, supply, and process efficiency. We are developing and implementing efficient stochastic modeling and optimization approaches for robust process design in the presence of these uncertainties. We are primarily focusing on studying the pre-treatment and hydrolysis steps of the process. We have developed detailed reaction kinetic models from literature for these two processes and have conducted stochastic simulations to quantify the impact of uncertainties. We have performed global sensitivity analysis on these models to identify key model parameters.

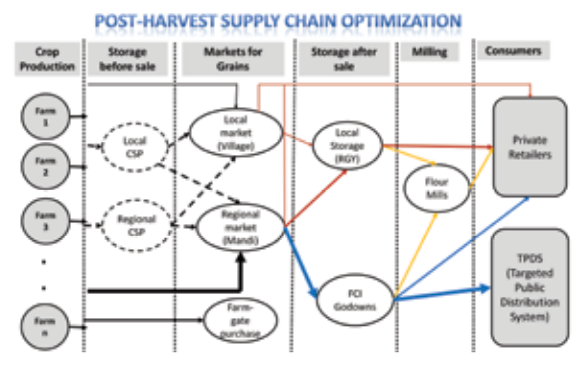

Grains such as wheat and rice suffer extensive losses along the post-harvest supply chain in India. Minimization of these losses is necessary yet challenging due to the highly complex nature of the supply chain. This work aims to determine the best combination of alternatives using optimization theory. We have developed a large scale optimization model for the post-harvest supply chain of wheat in India. The decision variables are the supply chain network links, flow of wheat along these links, and location and size of storage facilities. The objective function is minimization of the total cost and post-harvest losses