Venkat Gundabala

Core Faculty

Associate Prof.

241, Chemical Engineering

Core Faculty

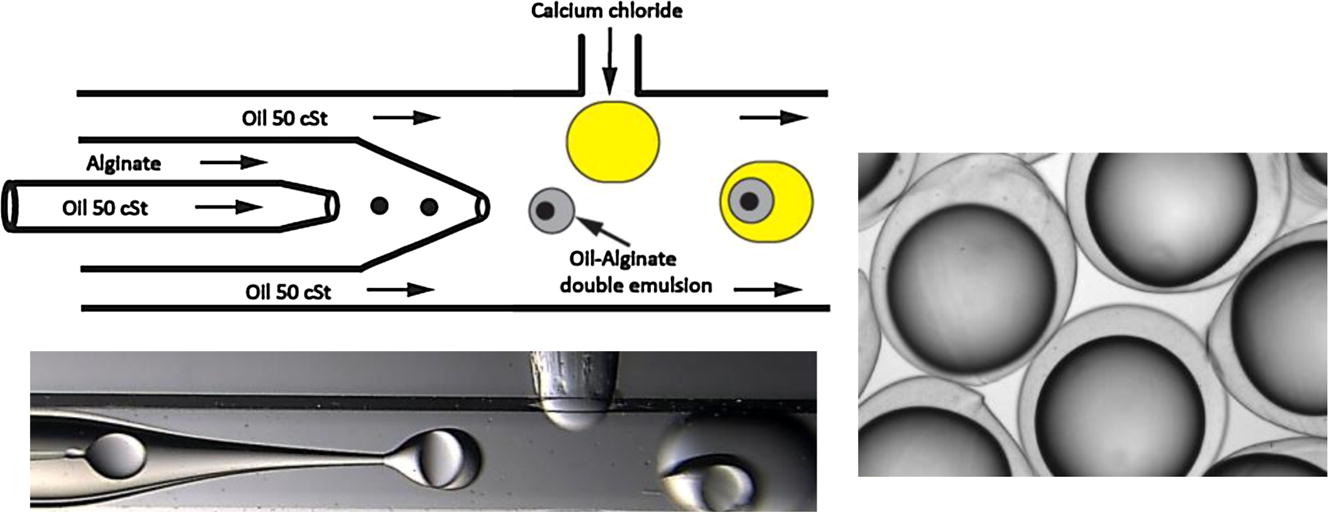

Associate Prof.

In one of the core areas of the lab, we use microfluidics as a tool for generation of biomaterials such as microparticles, microcapsules, and microfibers which have applications in drug delivery, tissue engineering, disease diagnosis, electronics, and textiles. We design and fabricate various types of glass-based and glass-PDMS based microfluidic devices to generate these biomaterials. In various projects over the years, we have developed and implemented on-chip solidification techniques that include droplet coalescence coupled with chemical gelation, electric field coupled with photopolymerization, and chemical gelation in the presence of electric fields. The generated biomaterials are currently being used for biological applications such as eradication of biofilm, cancer biology and drug delivery, and water treatment. There are various ongoing projects in these three areas of application.

Figure 1: 3D glass-PDMS hybrid microfluidic device for fabricating oil-alginate microcapsules through chemical gelation

Averting or impeding microbial growth on surfaces is of prime importance in architecture, healthcare, and textile industries. In buildings, the colonization of microbes on the surface causes defacement and physical damage to the building structure. In the healthcare industry, the proliferation of microorganisms on medical devices increases health risks for patients. In the textile industry, the growth of microbes on fabrics leads to several undesirable effects such as degradation, foul odour, and health risks. A promising strategy for overcoming microbial growth in various sectors involves, coating the surfaces with materials that can resist microbial adhesion and colonization. Inorganic nanomaterials or organic materials with inorganic inclusions are widely used as antimicrobial coatings.

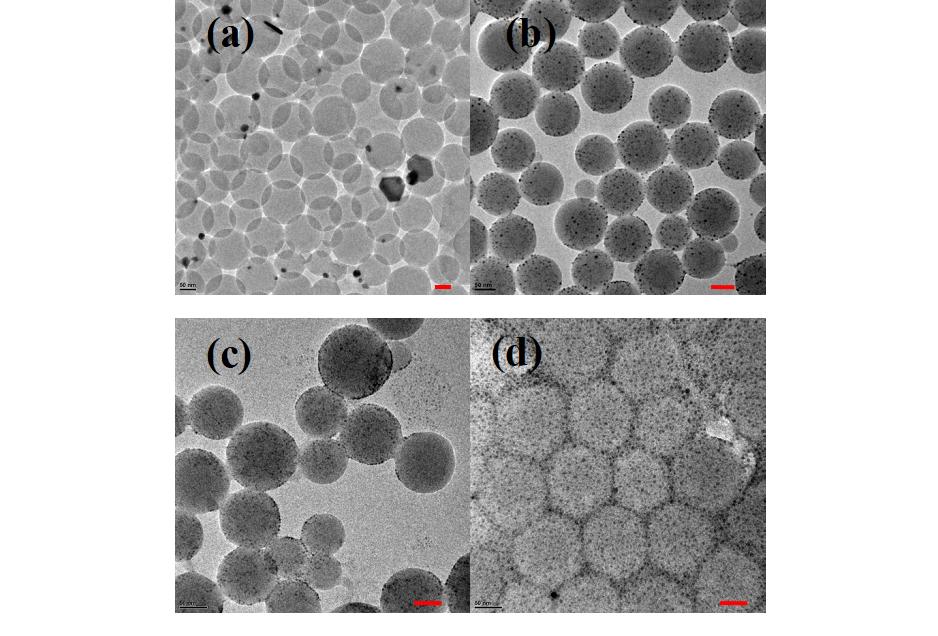

More recently, waterborne nanocomposites are being designed to have multi-functional properties such as antibacterial activity, photocatalytic activity, and electronic properties. Ongoing and past projects in the lab include investigating the film formation and antibacterial properties of latex nanocomposites containing metallic nanofillers and halogen complexes as antimicrobial elements. Particular focus is on the distribution of the metallic filler and halogen complexes in the dried films. Since the coating is surface-oriented, special attention is given to investigate antibiofilm properties of the films. The developed technology is tuned to improve the antibacterial properties of the metallic and halogen-based latex nanocomposites.

Figure 2: Silver nanoparticle coated polystyrene latex with coated nanoparticle size decreasing from (a) to (d)

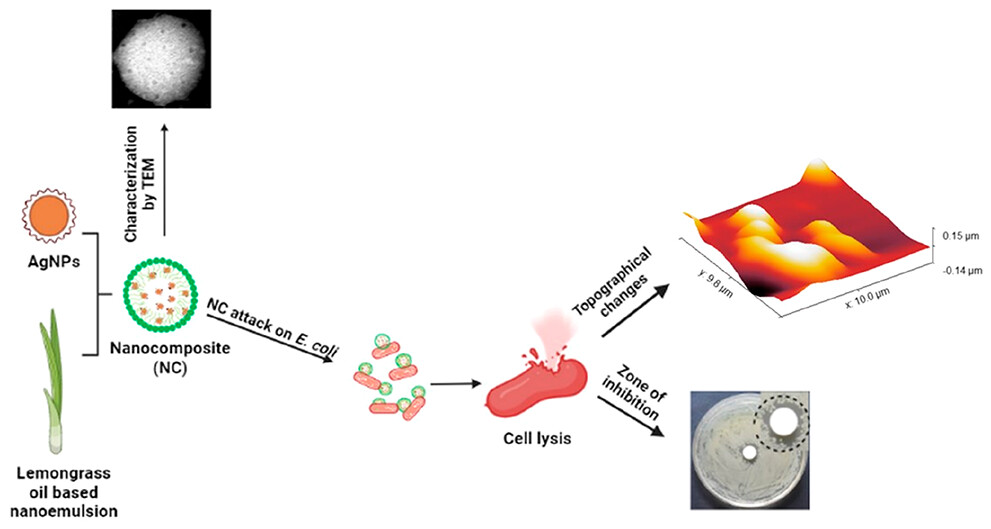

Food-borne diseases encompass serious health issues in approximately 30% of the population by consumption of foods carrying pathogens. Several pathogenic bacterial strains viz; Escherichia coli, Salmonella spp. Lysteria monocytogenes, Staphylococcus aureus, and Clostridia spp cause food infections. To avoid food spoilage and increase the shelf life, various packaging materials are available that have shown antimicrobial activity but the source of materials are either chemical or non-renewable. Hence, application of these materials as good packaging materials has become a global concern. We are currently developing a nanocomposite film comprising of, silver nanoparticles and nanoemulsion impregnated into biopolymer, as an active packaging material for protection against pathogenic E. coli. This work bears the potential to deliver an ideal bio-based antimicrobial food packaging, which could be the substitute for petrochemical plastic in a more efficient and sustainable manner.

Figure 3: Synthesis and testing of antimicrobial nanocomposite which is to be used as active agent in bio-based food packaging