K. V Venkatesh

Core Faculty

Professor

136, Chemical Engineering

Core Faculty

Professor

Swaranajayanthi Fellowship 2004 From Department of Science and Technology

Anil Kumar Bose Award 2004 From Indian National Science Academy

INSA Young Scientist Award 1999 From Indian National Science Academy

INAE Young Engineer Award 1998 From Indian National Academy of Engineers

Amar-Dye-Chem Award 1998 From Indian Institute of Chemical Engineers (IIChE)

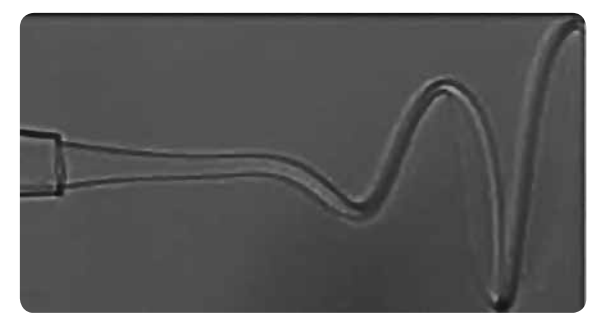

Cell microencapsulation is one of the most elegant and emerging approaches to targeted cell-based drug delivery. The technique involves immobilization of drug–laden cells inside a semi-permeable membrane, usually a polymeric microparticle. This approach overcomes the graft rejection problem usually associated with cell transplantation. Microfluidics offers a promising route to generation of polymeric microparticles which act as carriers of the drug-laden cells. The low flow rates involved in microfluidics allow precise control on the size of the microparticles. In this project, we are developing a microfluidics based technique for the controlled generation of polymeric microparticles and the subsequent encapsulation of drug laden cells. The idea is to develop a core-shell morphology which will allow encapsulation of multiple types of cells within the same particle providing distinct advantage over single cell type carrying particles. The project involves cell viability tests and drug release kinetics studies for encapsulated cells.

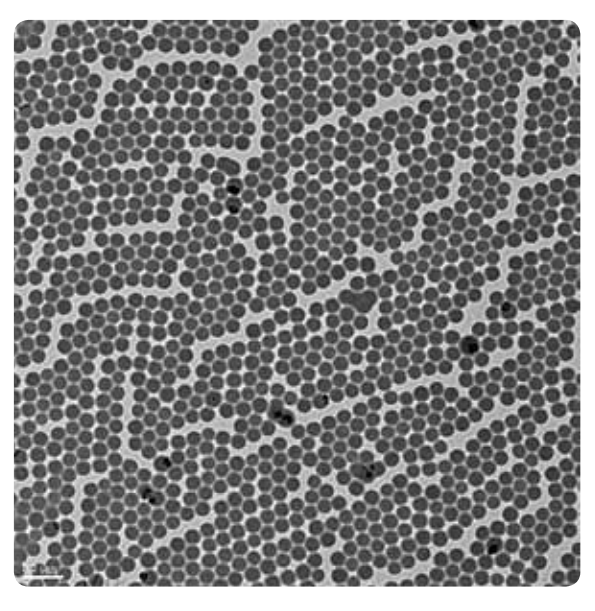

Preventing or inhibiting the growth of micro-organisms on surfaces is of prime importance in the healthcare and textile industries. In the healthcare industry, proliferation of micro-organisms on medical devices increases the health risk for patients. In the textile industry, growth of microbes on fabrics leads to several undesirable effects such as degradation, foul odour, and health risk. A promising strategy to overcome microbial growth involves coating the surfaces with materials that can provide resistance to microbial colonization. Inorganic nano materials and organic materials with inorganic inclusions are being widely used as anti-microbial coatings. More recently, water-based organic-inorganic nanocomposite materials are finding applications as functional coatings and specifically as anti-microbial coatings. In this project, we are investigating the film formation of organic-metallic latex nanocomposites. Special focus is on the distribution of the metallic filler in the dried films. The antibacterial properties of the obtained films are to be investigated. The synthesis technique is tuned to improve upon the film forming and antibacterial properties of the metallic-based latex nanocomposites.