Supercritical Fluid Extraction (SCFE) Technologies from IIT Bombay:

Potential of SCFE:

Worldwide, Supercritical Fluid Extraction (SCFE) Technology has emerged as a superior alternative to the conventional techniques for extraction of natural products in food, pharmaceutical and chemical industries. India with its rich botanical resources has very high potential for the use of SCFE to achieve value addition to its traditional export of natural materials in raw form. Thus use of SCFE technology can help Indian industry to gain its

share in rapidly growing international market for high quality, value added natural products.

Supercritical Fluid Extraction (SCFE) Technology , indigenously developed by Indian Institute of Technology, Bombay (IITB) has been successfully commercialized. IIT Bombay is presently equipped to help the user industry through 'Concept to Commissioning' of their ventures in the field of Supercritical Fluid Extraction.

Applications developed at IIT Bombay (in the arena of natural products) include:

• Decaffeination (coffee & tea)

• Hop extracts (bitter)

• Spice extracts (oil & oleoresin)

• Flavours & fragrances

• Food colours

• Food preservatives

• Herbal medicines

• Pesticides (neem)

• Deoiling of fast foods

• Cholesterol free food products

• Nicotine / tar free tobacco

Challenges:

Compared to traditional extraction technologies, SCFE is comparatively more capital-intensive due to the requirements of high pressure operation (100-500 bar) and very accurate process control. But more importantly, the high premium charged by foreign equipment / service providers based on novelty of this technology substantially increases costs of SCFE plants, making the imported SCFE technology economically non-viable in

developing countries like India. These are primarily the reasons why although SCFE has been successfully commercialized in developed countries for more than twenty-five years, it is yet to achieve its full potential in India.

IIT Bombay’s Contribution:

Indigenous innovative design, development and manufacture of SCFE plant and equipment so as to optimize the capital investment have been the key elements of the technology developed at IIT Bombay. Today in association with an industrial partner, we internationally offer indigenously developed, world-class SCFE plants with the following distinctive features:

• Substantially lower cost than the imported equivalent: thus making the SCFE technology economically viable.

• Innovative features in Hardware as well as Processes (Software).

• Complete inspection and certification of all equipment manufactured by a reputed international third party inspection agency.

• Support of continued R & D effort in newer product / process development.

• Availability of total technical support / services to user industries.

SCFE technology from IIT Bombay has been able to successfully compete in the international market with established suppliers from Europe, USA, Japan etc. Over ten SCFE plants have been manufactured and supplied, including one export order from Sri Lanka. Recently a larger commercial scale SCFE plant has been manufactured and installed for a 100 % EOU company from India.

What is SCFE?

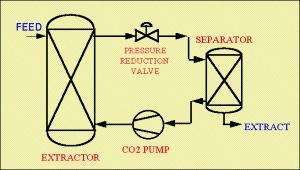

SCFE is a two-step process which uses a dense gas as a solvent e.g., carbon dioxide (CO 2 ) for extraction, above its critical temperature (31 o C) and critical pressure (74 bar). The feed, generally ground solid, is charged into the extractor. Supercritical CO 2 is fed to the extractor through a high pressure pump (100-500 bar). The extract laden CO 2 is sent to a separator (60-120 bar) via a pressure reduction valve. At reduced temperature and pressure conditions, the extract precipitates out in the separator. The extract free CO 2 stream, leaving the separator is then recycled to the extractor. In the case of liquid feed, the extractor is modified into a column through which feed and the supercritical CO 2 is fed either co-currently or concurrently

SCFE Pilot Plant at IIT Bombay

India with its rich botanical resources has very high potential for the use of SCFE to:

• Achieve value addition to its traditional export of natural materials in raw form.

• Gain share in rapidly growing international market for high quality natural products.

However, SCFE is comparatively more capital-intensive, due to the requirements of high pressure operation (100-500 bar) and very accurate process control. In addition, the high premium charged by foreign equipment / service providers based on novelty of this technology adds substantially to the cost of SCFE plants, making the imported SCFE technology economically non-viable in developing countries like India. Thus indigenous innovative design, development and manufacture of SCFE plant & equipment to optimize the capital investment and availability of technical support / services locally, represent the key requirements for in adopting SCFE in India.

With considerable experience and expertise in fundamental and applied aspects of SCFE processes IIT Bombay took up the challenging task of developing world-class SCFE technology with a primary aim of making it truly economically viable. IITB has developed for the first time in India, as a part of the Planning Commission funded Technology Development Mission (TDM) on Food Process Engineering (1993-98):

(i)Supercritical Fluid Extraction Systems design,

(ii)Process engineering packages, for a variety of natural products for applications in foods, flavour, pharmaceutical, herbal, cosmetics sectors.

(iii)A versatile state-of-the-art SCFE prototype plant designed, erected and commissioned at IITB, for the purpose of technology demonstration, process development and generation of test marketing samples for user industry.

(iv)Basic and detailed engineering for SCFE plants up to 1500 tons per year feed processing capacity.

AWARDS & RECOGNITIONS:

The team members have received following Awards, recognition for their contribution in development of the said SCFE technology at IIT, Bombay:

• NOCIL Award for “Excellence in Design / Development of Process Plant / Equipment”, 1997, from the Indian Institute of Chemical Engineers (IIChE).

• Suman Sharma National Design Award from the Institution of Engineers (India),for the year 1999.

• Young Engineer 2000 Award from the Indian National Academy of Engineering(INAE), for the year 2000.

• Dr. P. K. Patwardhan Award for technology Development and Transfer, 2001.

A book has also been authored by Prof. M. Mukhopadhyay titled 'Natural Extracts using Supercritical Carbon Dioxide', published by CRC Press, USA. The book has been well received and appreciated internationally.

Select Details of the Products Commercialized:

| PARTICULARS | EXPORT | DOMESTIC | |

| PRODUCT TYPE: | Supercritical Fluid Extraction plant having 2 x 10 liter extractor capacity |

Supercritical Fluid Extraction plant having 1 x 4 liter extractor capacity |

Supercritical Fluid Extraction plant having 2 x 200 liter extractor capacity |

| CLIENTS NAME: | Paints and General Industries (Exports)Ltd., Colombo, Sri Lanka | Alps Industries Ltd.,Ghaziabad, India.(100 % E.O.U. Company) | Sami Labs Ltd., Bangalore, India.(100 % E.O.U. Company) |

| STATUS: | Order executed in April 2000 | Order executed in February 2001 | Order executed in March 2002 |

| SPECIAL FEATURES: |

|

|

|

| COMMON FEATURES: |

|

||

The other organizations to which SCFE plants and systems have been sold by M/s Deven Supercriticals Pvt Ltd., during the period 2002 – 2007 are as follows:

| Sr. No | Organization Name | Type of SCFE Plant |

| 1 | National Botanical Research Institute, Lucknow | Pilot Plant |

| 2 | Patkai Herbs and Spices Ltd., Guwahati | Pilot Plant |

| 3 | Sami Labs Ltd., Bangalore | Pilot Plant |

| 4 | Sami Labs Ltd., Bangalore | Capacity Expansion for SCFE plant supplied in 2002 |

| 5 | Tea Research Association, Toklai, Assam | Pilot Plant |

| 6 | Regional Research Laboratory, Jammu | Pilot Plant |

| 7 | Ace Agro, Lonavala, Maharashtra | Commercial Plant |

Innovative Features of IIT Bombay SCFE Technology:

The SCFE technology from IIT-Bombay has following innovative features, which successfully meet above challenges leading to high productivity with safety and reliability:

a) Inherently safe design for the quick acting closure (C-Clamp) for pressure vessels:

The high-pressure extractors need to be opened at the end of every batch for feed change. Our quick acting closure C-Clamp can be opened only when extractors are depressurized to atmospheric pressure. This is an in-built feature of the design and does not require any instrumentation / electric switches / interlocks which is the common practice followed by other suppliers.

b) Design of extractor feed basket:

A number of designs have been evolved for extractor feed basket, suitable to handle requirements of various natural products, to achieve high extraction efficiency.

c) Design of special internals for Separator vessels to achieve complete recovery of extract:

These special internals are important not only for improving the percentage recovery of extract but also to avoid contamination of carbon dioxide, which is recycled in SCFE process.

d) Design of cost effective and easy to fabricate high pressure heat exchangers:

These special heat exchangers designed for tube side service pressure up to 500 bar, contribute substantially to overall cost optimization of SCFE plant.

e) Modeling and Simulation of SCFE processes for complex natural products:

Natural extracts are typically mixtures of variety of molecules having different physical and chemical properties. Thus understanding and prediction of their interaction with Supercritical CO 2 plays key role in process development and optimization, as well as scale up.

f) Development of cost effective pre-treatment process:

The natural raw material (feed) needs to undergo pre-treatment such as drying and grinding prior to the extraction step. It is important to avoid any loss of desirable components during this operation. Generally very expensive methods like Freeze-drying and cryo-grinding are typically employed for this purpose. We have developed very cost effective methods suitable for Indian conditions, to achieve

desired results.

g) Development of user friendly / inherently safe control logic and safety interlocks:

SCFE is a high pressure batch process and also requires accurate monitoring and control of process variables such as pressures, temperatures and flow rate at different sections of the plant. Fail safe control and safety interlock system has been developed.

Other notable feature is that, the designs developed incorporate state of the art systems and components. The imported component in the total system is a modest 20 % by value, comprising items such as high pressure liquid CO 2 pump, high pressure control valves, fittings etc., which are not currently manufactured in India to the stringent specifications required.

National Relevance of SCFE Technology:

The SCFE technology from the IIT-Bombay has following features, which may be of

national relevance:

1. This effort has resulted in generation of expertise and vendor development for engineering of high pressure systems conforming to international standards.

2. It is well established fact that due to superior quality and yield of products from SCFE (without loss of heat sensitive and volatile components, free of residual solvent and microbial contaminants, Eco-friendly process etc.), they are preferred by consumers. Thus, cost effective SCFE technology is the right answer to India's export and domestic needs.

3. The SCFE plants based on technology from IIT, Bombay cost substantially lower than the imported equivalents. This world-class but cost effective SCFE technology from IIT, Bombay can now be used for effectively tapping the rapidly growing international market of quality, value added natural products.

4. The present international trend of increasingly stringent regulations regarding residual organic solvents in processed food product clearly indicates that the conventional solvent extraction process may be phased out in the near future.Already chlorinated solvents are banned from their use in food processing. SCFE has successfully and totally replaced them in applications like decaffeination of tea and coffee, hops extraction etc. Similar trend is observed in other applications as well.

5. Relatively higher investment requirement of SCFE process is well compensated by other benefits of the process such as: low solvent (CO 2 ) cost, lower batch times, higher concentration of active / desirable components in the extract, no pollution control related costs etc.

6. There is practically no effluent generation in SCFE; hence the process is eco-friendly and pollution free. And thus can easily comply with ISO 14000 certification, which will become necessary for future exports.

7. The extracted residue (cake) from the SCFE process does not undergo any degradation, unlike in solvent extraction and steam distillation. Thus it retains all the useful natural substances such as edible proteins etc. This can be sold as a high value by-product to give additional revenue to the project. This will also eliminate problem of residue disposal as in case of solvent extraction or steam distillation

8. The accurate control over the SCFE process achieved with state-of-the-art instrumentation and control system ensures high consistency in the quality of the final product. This is an important factor for sale in the world market.

9. The SCFE plant based on IIT Bombay technology is a multi-product processing facility. Thus the same hardware can also be used for extraction of a large and diverse range of natural products, such as Spice oils and oleoresins, food colours,medicinal extracts, caffeine from coffee and tea, nicotine and tar from tobacco,cholesterol from egg powder, natural pesticides from neem, fragrances etc. Many other applications are also established for the SCFE process in non-food areas.

10. In recent past adoption of SCFE technology in India, was essentially deterred due to very high premium charged by the foreign SCFE equipment / service suppliers,which affected its economic viability. But now IIT, Bombay has developed world class SCFE technology in India, to make it cost effective. Thus SCFE, which is a superior technology in all respect, is now made truly economically viable. Thus use of conventional technologies like solvent extraction (using hexane or hydro-flouro carbons) and steam distillation may not be now appropriate for Indian industry.Therefore, adopting SCFE can help India gain a strong presence in the world market of value added natural products.

11. The value of the technology developed and commercialized is to be assessed in the context of rapidly emerging new applications of Supercritical Fluid technology.Some of the potential applications include:

(i) Microfine / nano particle formation for drug delivery / control release applications.

(ii) Eco-friendly precision cleaning of electronic and optical components.

(iii)Eco-friendly textile dyeing.

(iv) Drying of Aerogels to produce high quality thermal and sound insulation material.

(v) Neutraceutical, herbal extracts of pharmaceutical value.

(vi) Synthesis and processing of polymers: Commercial facilities for synthesis / processing of polymers using supercritical fluids are being

established in several countries.

The SCFE technology has been able to successfully compete with established suppliers from Europe, USA, Japan etc. In the evolving scenario, experience and capabilities developed through the current commercialization efforts are likely to yield substantial technical and commercial benefits in the coming years.