Sandip Roy

Core Faculty

Professor

Core Faculty

Professor

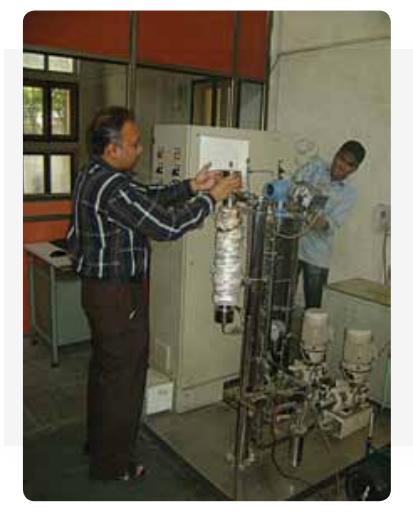

NOCIL Award for Excellence in Design/Development of process plant/Equipment IIChE (1997) for design and development of Supercritical Fluid Extraction Pilot Plant.

P K Patwardhan Technology Development Award for Development and Transfer of Supercritical Fluid Extraction Technology (2000-2001)

Our current research interests comprise: (i) Process Safety and Risk Management; (ii) Combining Safety and Sustainability Principles for Process Design, and (iii) High-pressure Fluid-based Processing. The sub-areas within these domains that are being investigated presently are:

Risk-based Decision-making for Process Safety Management, Cultural Determinants of Process Safety Management Systems, and Industrial Risk Governance; Development of Safety and Sustainability Metrics, Decarbonization of the Indian Oil and Gas Industry

Solid Nucleation from Supercritical Fluids; Anti-solvency-based precipitation of Active Pharmaceutical Ingredients (APIs) from Subcritical fluids; Gas-bubble Surface enabled Heterogeneous Nucleation of Solids, Supercritical Fluid-based Textile Dyeing, Supercritical Fluid-based Polymer Recycling

Process Safety / Risk Management

In the area of process safety management, one of our current focus is on risk-based optimization of investment in safety systems that is expected for a green-field project. In addition, the framework for optimizing such an investment is being extended to aid decision-making for fixing annual safety expenditure for an established plant. Both these categories of expenditures are required to be met for a typical process plant. The rationale for investigating this area is to develop an over-arching framework that may allow an organization to optimize safety investments while at the same time meeting safety regulations and the need for insuring select critical risk sources.

The other area of research encompasses the role of national and organizational culture in determining the safety culture of an organization. It is well recognized today that cultural attributes of a people can subtly yet strongly determine the beliefs, attitudes and eventually safety policies of an organization, and that the efficacy of such “habits and strategies” can constitute critical underlying factors that shape both the safety and business performance of an organization. We wish to understand the impact that safety culture has on organizational performance.

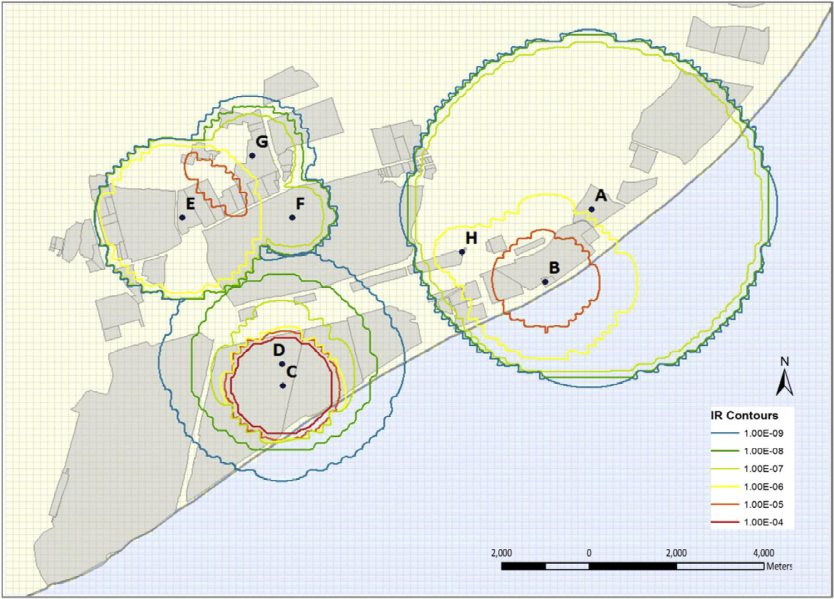

Other areas of ongoing research that are expected to be consolidated are: Risk-based Process Plant Layout Optimization; Risk-based Land-use Planning around Process Facilities, and Development of Methods to incorporate Safety and Sustainability in Process Design, and Industrial Risk Governance, Risk-based Maintenance Scheduling.

On the domain of combined analysis of safety and sustainability our current work focuses on development of metrics / indices for human development that is sustainable. The principles of safety and sustainability are also being merged into a composite framework for analysis of technologies.

High-pressure (Supercritical) Fluid-based Processing

The other strand of research in our laboratory is on high-pressure fluid-based precipitation of solids, both on experimental and theoretical fronts. On the experimental side, development of more sophisticated systems for tracking and measuring particle nucleation rates, both for liquid-phase anti-solvency-based nucleation as well as for gas-surface mediated particle.

formation is being explored. The prospect of using gas bubbles to precipitate solid particles offers distinct advantages, but remains a largely unexplored area. New research results in this domain can potentially alter the present industrial practice of using seeded crystallization processes for generation and control of size of API particles.

In the area of theoretical representation of such precipitation processes there are significant lacunae of the classical nucleation theory (CNT) that have been recorded in the existent literature as well as in our ongoing work. This pertains to the mismatch between the predicted homogeneous and heterogeneous rates and those measured experimentally. The problem needs to be addressed by a better formulation of the details of physical processes underlying the nucleation phenomena and their corresponding mathematical representation. In addition, the problem may be addressed through Molecular Dynamic Simulation, a research program that has been initiated presently.

Polymer recycling poses a critical challenge today, especially those containing halogens and other hazardous moieties. Presently a series of studies are underway in our laboratory to recycle PVDC using supercritical water as a medium.