Reaction Engineering and Catalysis

Catalytic Performance Evaluation

Screening of optimal catalysts, contacting patterns, and kinetic studies for acid-catalyzed and redox chemistries through gram-scale batch experiments, followed by continuous fixed-bed experiments under atmospheric and high-pressure conditions. We monitor the extent of the reaction through Gas chromatography (GC) and High-Pressure Liquid Chromatography (HPLC) techniques. We also do reaction mixture profiling through 1D and 2D High-Resolution Mass Spectrometry coupled with GC and HPLC. Most of our work goes into the development of novel heterogeneous catalysts for conventional homogeneously catalyzed industrially relevant processes.

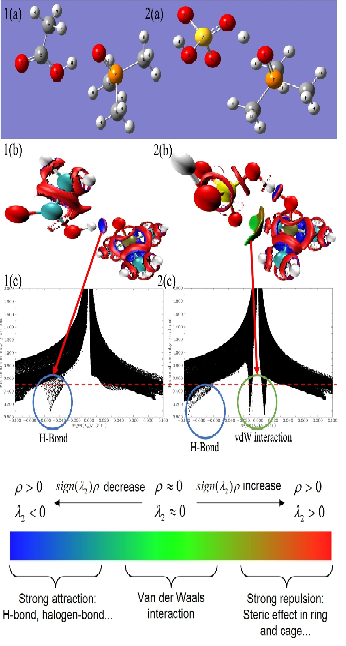

Surface Characterization & Rational Catalyst Design

We employ sophisticated characterization techniques like Solid-state NMR, TGA, DRIFTS to probe the surface acidity of heterogeneous solid-acid catalysts like Ion-Exchange Resins, Zeolites, supported Heteropolyacids, etc. The knowledge of surface acidity helps in choosing a catalyst for a certain chemistry. For correlating catalytic activity with the structure of the catalyst in redox chemistries, we employ X-ray techniques like XRD, XPS, EXAFS, etc. We work on protocols to obtain highly dispersed supported Nanocatalysts for redox reactions like hydrogenation of CO2, Furfural, etc. We also work on shaping the novel catalysts into extrudes or pellets for fixed-bed experiments.

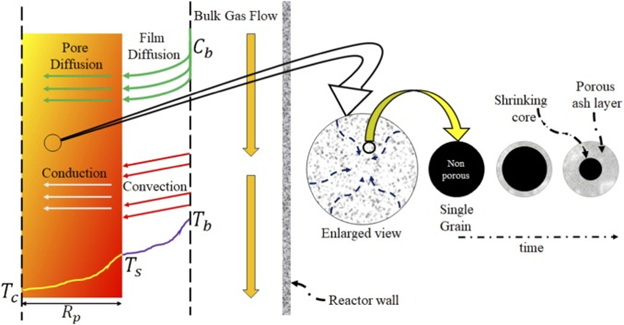

Green chemistry and Green Engineering for the production of fine chemicals:

Both green chemistry and engineering are the important elements of sustainable development. In my group, we work on converting the existing environment unfriendly reaction to their clean and neat counterparts through catalyst identification/development or process intensification. The reactions of interest are liquid phase or Gas-liquid reactions with catalysts such as metal oxides, zeolites, and ion exchange resins. Developing green processes from bio feedstock such as furfural is also of interest to us. The work elements include catalyst characterization, generation of kinetic data, improvement of performance by manipulation of catalyst composition or by reaction conditions, design of reactors, downstream processing and techno-enviro economic feasibility. Some of the products include, carboxylic esters, ethers, substituted aromatics/heterocycles, methyl pentenone, styrene oxide etc.