Prof. Sharad Bhartiya Research Group IIT Bombay

Automation Lab

Process Control and Optimzation

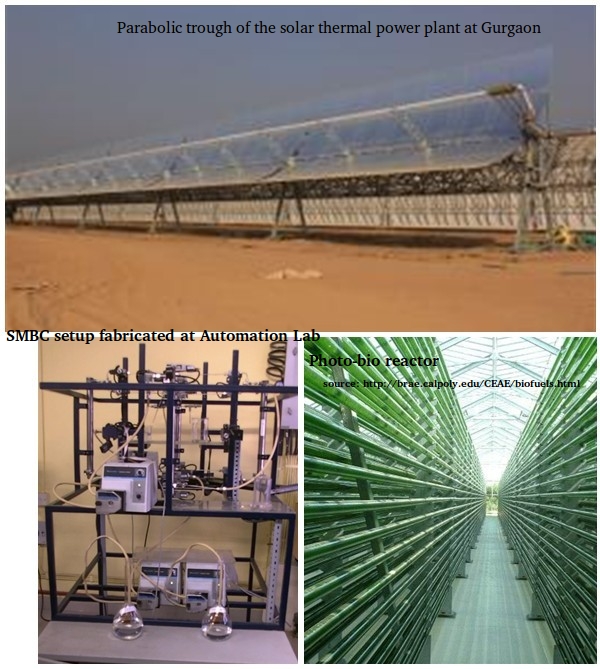

In this area, we use optimization and control tools to obtain strategies for operation of industrial processes. Some of the processes currently under study include a solar thermal power plant, a bio-refinery and a simulated moving bed chromatography process.

Major research focus in these are :

- Modeling and optimal operation of solar thermal power plant (wtih Prof. Mani Bhushan): The energy from the sun is readily available and abundant on the tropical areas of the earth. Utilization of the solar energy as a clean and renewable energy resource benefits the mankind as a whole by substantially contributing towards improvement of air quality, energy security & economic development. In order to attain a desired electrical power production on a large-scale, the process has to be viable, both from operational as well as economical aspects. From an operational point of view, apart from other requirements, an effective advanced process control strategy has to be implemented for proper functioning of the plant, irrespective of fluctuations in operating parameters (for example, energy input from sunlight, flow rates of the working fluid) that may occur. The ongoing research work aims at designing an advanced control scheme needed for this solar thermal power plant

- Modeling optimal control of micro-algal biorefinery (with Prof. Yogendra Shastri): With the reserves of conventional energy sources (coal and crude oil) fast depleting, discovery of the potential of different non-conventional resources as the source of energy is the need of the hour. Energy from biomass is one such promising candidate. But, concerns of food security limit the utilization of food crops such as corn and sugarcane, while the utilization of lignocellulosic plants is typically limited by land availability. In this respect, algae has been regarded as a better alternative due to its high yield per unit area, which makes it very attractive to places like India with limited availability of arable land. Despite these obvious advantages, biofuels are not competitive with conventional fuels. Our work aims at developing a bio-refinery as a highly integrated and flexible manufacturing system with a number of end-products ranging from biodiesel and bioethanol to pharmaceutical intermediates . It is expected that such an approach will make bio-fuels a viable alternative.

- Optimal operation of SMBC: Simulated Moving Bed Chromatography (SMBC) is an adsorption based continuous separation process. The parex process for xylene separation is a popular example in the petrochemical industry. Similar applications are found in the pharmaceutical industry. SMBC is a technical realization of the counter current adsorption process approximated by sequentially switching the inlet and outlet valves of interconnected columns in the direction of fluid flow. Due to the switching nature, the process is dynamic in nature and only cyclic steady state operation can be achieved. In this work, we use dynamic optimization to obtain optimal transitions between optimal operating points.