Surfactant therapy in

Respiratory Distress Syndrome (RDS)

u

Respiratory Distress Syndrome affects 2/3rd of all preterm infantsu

Cause: Quantitative or functional deficiency in lung surfactantu

Modes of therapy:l Mechanical ventilation

l Supplemental oxygen

l Surfactant replacement - Physiologic

u

Role of surfactant:l

Reduction of surface tension at air-alveolar interfacel

Prevention of alveolar collapsel

In accordance with Laplace law: D P =

Findings & Conclusions

u

Pulsating bubble surfactometer relevant to lung alveolar systemu

Frequency dependant response of surfactants:l PCPG best at 20 cpm

l PG best at higher frequencies (40 & 60 cpm)

u

Monolayer studies by L-B troughl

PCPG better than commercial surfactantsu

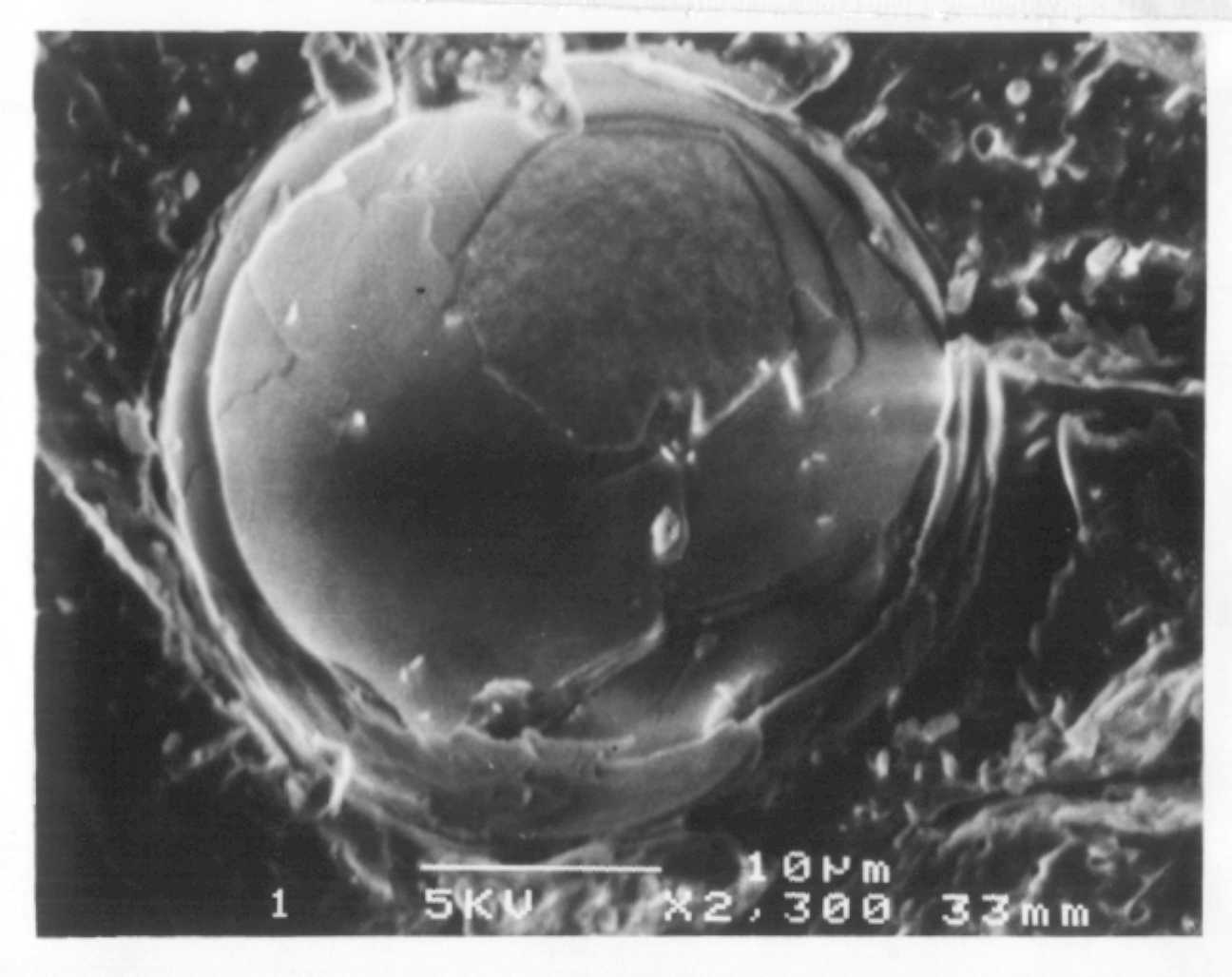

Morphological studies by Cryogenic SEMl

Presence of tubular myelin with addition of calcium (5mM)l

PCPE & PCPG form larger liposomesu

New, superior formulations with adjuvants developed for RDS.(Patents in pipeline.)

Pulsating Bubble Surfactometer (Schematic)

Ultramicroscopy techniques for

soft solids and complex liquids

Soft solid and complex liquids are ubiquitous in chemical engineering. Research into their structure needs specialized techniques for investigations because samples are neither a solid nor a liquid but something in between. Persistent efforts have gone on in developing in Cryo SEM techniques with freeze-fracture facility at the Chemical Engineering Dept. This technique which involves viewing microstructures of wet samples, with a resolution of 1 micron, maintaining the vacuums used in conventional SEM. The various steps involved are

This expertise has been developed over the years in the Chemical Engineering Department and the possibly the only laboratory in India where such a facility exists. Some of the samples which have been investigated are

Myelins: Structure, coiling and ordered nanoparticles

Surfactants are important component in many biological and industrial systems as well as in various consumer products. Surfactants form a variety of microstructures in solution, some of which are equilibrium and others non-equilibrium microstructures. All such microstructures are surfactant aggregates, also known as "association colloids". During the dissolution of a surfactant in the solvent, various types of non-equilibrium microstructures have been observed. The most interesting and fascinating non-equilibrium microstructure is the "myelin figure" that forms by a dynamic processs called "myelin growth".

SMyelins are highly viscous, gel-like, microstructures consisting of multilamellar tubules of alternating amphiphile bilayer and water layer with a core axis of water (fig 1). The structural features of myelin figure is essentially similar to that of the nerve myelin sheath, the white matter insulating the nerves, which allows the conduction of impulses from one part of the body to the other. Thus the bilayers of myelins have structural resemblance with biomembranes.

Fig.1 : Schematic representation of a Myelin

Fig.1 : Schematic representation of a Myelin

(from http:// markun.cs.shinshu-u.ac.jp/artscape/artsc/reci/myeline.html ).

This phenomena is a manifestation of dynamic interface instability involving rearrangement of the bilayers of the surfactant lamellar phase (La ). It is a sort of bilayer reorganisation involving swelling of the surfactant lamellar phase.

We have used our microstructure expertise to probe the strucutre and coiling of such myelins, and to use them as reactors to produce nanoparticles. The most dramatic finding is the helical structures and ordering of nanoparticles.

|

|

|

|

Myelin Growth in AOT/water system

|

|

|

|

(a) (b) (c)

Coiling in AOT/ 5 wt% aqueous PTS solution system

|

|

|

Formation & ordering of CaCO3 nanoparticles on myelin structures

Special Materials: COMPOSITE POLYANILINE-STAINLESS STEEL MEMBRANE for gas separation

u

Composite membranes of polyaniline S.S. prepared by electrochemical polymerizationu

Microstructural studies of the formation of the polymer in the tortuous pores of the SS substrate done. Graded growth seen.u

The bulk of the polymer was formed on the surface and within 200m m from the surface of the substrate.u

Electrochemically doping with various ions show a.l

Decrease in the fibrillar size of the polymerl

Permeablity can be changed sevreal foldl

Tuneablity of selectivity: nanoengineering

Microstructure of the composite membrane.

Integrated plant for Biomedical Optics

Technology developed and transferred:

u

Design and development of vertically integrated pilot plant for optical glass fibersu

Technology for conversion into light guide and image guide applications developed.u

Micro-optic devices like endoscopes developed. u

u

u

Plant was extended to include a microcapillary drawing system. One thousand meters was drawn with ±10m m tolerance.

Continuous pressing plant for microfiltration membrane production

u

Lab-scale, pilot-scale, and commercial scale plants were scaled-up and commissioned for production of cellulosic membrane filters for microfiltration of pharamaceuticals and use in biomedical devices.u

Down-stream conversion plant into finished products like blood filters and syringe adapters was developed. u

u