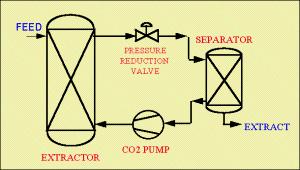

Supercritical Fluid-based Processing Technologies from IIT Bombay Supercritical Fluid-based (SCF) Processing has been a significant research focus at the Department of Chemical Engineering at IIT Bombay (IITB) for over three decades.Currently IITB houses a wide range of experimental facilities: from bench-scale setups to pilot plant. The principal areas of research are: • Extraction of natural products • Micronization and Encapsulation of high-value nutraceuticals and pharmaceuticals • Preservation of liquid and solid foods • Reactions in supercritical fluids • Pressurized Water-based extraction processes for natural medicinals and nutraceuticals Key SCF systems available at IITB: 1. Supercritical Fluid Extraction System: SCFE is a two-step process (see schematic below) which uses a dense gas as a solvent e.g., carbon dioxide (CO 2 ) for extraction, above its critical temperature (31 o C) and critical pressure (74 bar).The feed, generally ground solid, is charged into the extractor. Supercritical CO 2 is fed to the extractor through a high pressure pump (100-500 bar). The extract laden CO 2 is sent to a separator (60-120 bar) via a pressure reduction valve. At reduced temperature and pressure conditions, the extract precipitates out in the separator. The extract free CO 2 stream, leaving the separator is then recycled to the extractor. In the case of liquid feed, the extractor is modified into a column through which feed and the supercritical CO 2 is fed either co-currently or concurrently.

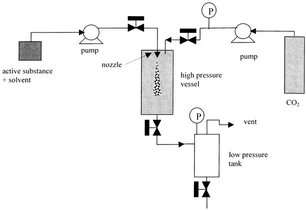

2. Supercritical Fluid Micronization/Encapsulation System: Particle design (micronization and encapsulation) is presently a major development of supercritical fluids applications, mainly in the pharmaceutical, nutraceutical, cosmetic and specialty chemistry industries. Typically, the supercritical fluid is used as an anti- solvent that causes precipitation of the substrate(s) dissolved initially in a liquid solvent. The supercritical fluid is pumped to the top of the high pressure vessel (see schematic below) by a high pressure pump while the active substance solution is introduced into the high pressure vessel through a nozzle. To produce small liquid droplets in the nozzle, the liquid solution is pumped at a pressure higher than the vessel operating pressure. Particles precipitate due to thee anti-solvent action of the supercritical carbon dioxide, and are collected on a filter at the bottom of the vessel. The fluid mixture (supercritical fluid plus solvent) exits the vessel and flows depressurization tank where the conditions allow gas-liquid separation.

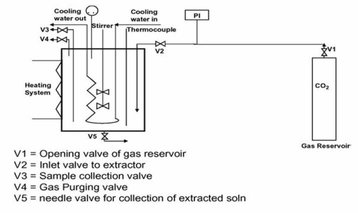

3. Pressurized Hot Water Extraction System: At normal conditions the dielectric constant value of water is quite high, but at sub- or supercritical conditions, it is lowered water can mimic the behaviour of both polar and apolar solvents, and hence allowing the solubilization of a wide variety of moieties normally not very soluble in water. Subcritical water extraction or Pressurised Hot Water Extraction (PHWE) is based on this unique solvent property of water. A very wide range of herbal products may be extracted efficiently using this process. The PHWE system schematic is shown below.

Hot water is pressurized using gaseous CO2 at a moderate (2–20 bar) pressure. The pressurized water is then used to extract the analyte from the plant matrix. The extraction efficiency depends upon: processing temperature and pressure, particle size of plant matrix, water to plant matrix ratio, etc. PHWE is suitable for a extraction of a various natural molecules: flavonoids, essential oils, saponins, etc.

Services offered to the industry:

The IIT, Bombay research team undertakes both fundamental and applied research in diverse areas of supercritical fluid technology. Apart from the study of a large variety of specific systems requiring SCF processing, the research experience has been translated into development of process and engineering designs of SCF systems (bench top to commercial scale) for:

(i) SCF-based extraction of natural products (spices, medicinal herbs, natural colours, flavours and fragrances, etc.)

(ii) SCF-based micronization and encapsulation of nutraceuticals and pharmaceuticals

(iii) Pressurized hot water extraction of herbals

The specific services offered to the industry are:

• Technology Consultation: Process Optimization; Selection / Choice of Viable Products; Selection of Optimum Process Plant Configuration, Feasibility Analysis

• Generation of Extracts for Test Marketing

• Contract Research

Contact:

The Principal R&D Team Members from IIT Bombay are faculty with the Department of

Chemical Engineering

• Prof Sandip Roy (sr [at] che [dot] iitb [dot] ac [dot] in, 91-22-2576 7249)

• Prof Madhu Vinjamur (madhu [at] che [dot] iitb [dot] ac [dot] in, 91-22-2576 7218)

• Prof Mamata Mukhopadhyay (mm [at] che [dot] iitb [dot] ac [dot] in; 91-22-2576 7248)

• For more information about Supercritical Fluid Processing Technologies from IITB

please visit: http://www.che.iitb.ac.in/online/services/technology-transfers

•Email: scfe [at] che [dot] iitb [dot] ac [dot] in